Have you been using semi-automatic heat sealers but now looking for something more? Are you a high volume producer, wanting to speed up your production and seal even faster to a rate of 1400 packs per hour, without a big increase in staff costs and minimum effort? Perhaps you have a number of different product ranges you’d like to seal using changeable tooling. Are you looking for increased efficiency with a printer or labeller option, sealing and labelling automatically at once?

Do you require confidence in a reliable sealing system which enables you to concentrate on other areas of your growing business? We’re aware your ability to deliver is crucial to your business, so we’ve invested in precision design and engineering to deliver consistently high performance at an impressive rate. If you’re ready to step-up to another level, the Soken HS52C linear automatic, rapid, heat sealer is ready to deliver the results you need.

This sealer delivers high speed production with a sealing rate of up to 1400 sandwich packs an hour. It provides consistent, reliable and exceptional results. Key to its impressive performance is an accurately controlled high temperature seal system and consistent pressure, together with a precision indexing system. This combined system has the ability to seal the very latest biodegradable cardboard packaging in a variety of sizes.

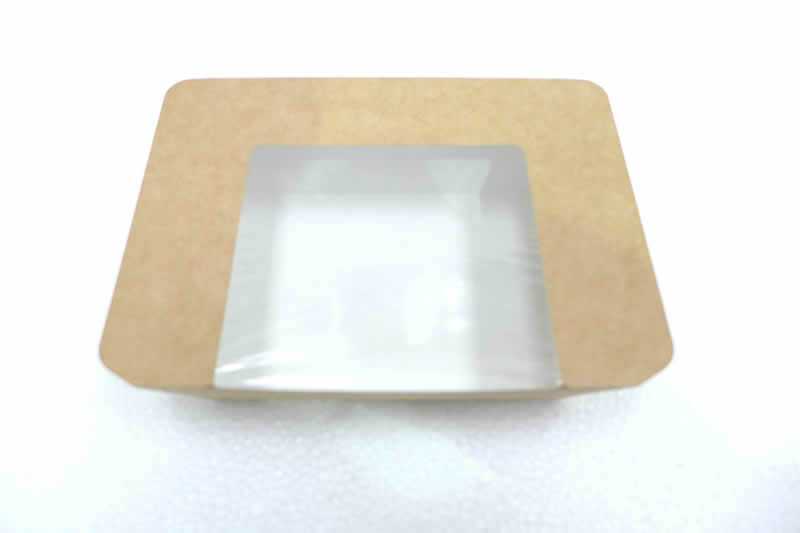

The accurate index location ensures sealing only occurs on seal edge areas of a pack. A cavity top tool design protects the product and pack window from heat during the sealing process. Precision tooling maintains accurate positioning of the packaging for optimum sealing. Printers and label applicators can be fitted prior to the integrated pack lift, rail ejection system.

Ideal for sealing: Sandwiches, wraps and salad boxes

Ideal users: High volume sandwich manufacturer

Sealing rate: 1400 packs per hour

Maximum seal area: 200mm x 270mm

Weight: 200kg

Height: 1.6m

Length: 2.5m

Width: 600mm

Power: 230V 50Hz 1 phase 6 Amps (120V optional)

Contact us now for more information about this product: Tel: +44 (0) 1256 892194 info@sokenengineering.com