From our experience working with food manufacturers for more than 10 years, we know that no matter what your business’s size, packaging integrity is absolutely critical to ensure product freshness, extend shelf-life, and maintain brand reputation.

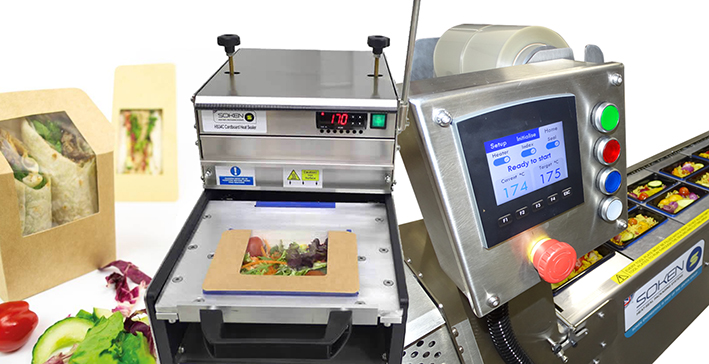

We have developed a large range of heat sealing machines which help businesses of all sizes achieve this, whilst also improving efficiency and their bottom line. Here, we take a look at the three different types of heat sealers so you can choose the right one for you.

| Type of heat sealer | Best for | Benefits | Our machines |

| Hand | Small producers | Affordable

Easy to use |

HS20FC, HS22C, HS25FC |

| Semi-automatic | Medium producers | Multi-pack sealing

Consistent temperature, pressure and time |

HS34CF, HS35AC |

| Automatic | Large producers | Can produce thousands of packs per hour

Fully automated with minimal human intervention |

HS52C, HS60C, HS55 |

What is a hand sealer?

Hand sealers are simple, hand-operated machines used to seal food trays, convenience food packs or other packaging. They require operators to manually place a tray or pack in the machine, pull a lever or bring the top sealing plate down to apply pressure to activate the sealing process, and then remove the sealed product. Machines like our HS20FC, HS22C, and HS25FC are examples of these compact sealers. They are ideal for small, lower volume users such as artisan food producers, cafés or delis, and small catering operators.

The primary benefits of these machines are their affordability and ease of use. They don’t require a lot of space either, making them a reliable and cost-effective solution for low-volume production.

Even our smallest machines feature adjustable digital temperature control to ensure the sealing temperature can be set to best suit the packaging type and remain consistent throughout.

What is a semi-automatic heat sealer?

Semi-automatic heat sealers balance human control with automated functions. In a semi-automatic process, the operator places the tray or pack into the machine, but the sealing is performed automatically by the machine – either through compressed air or electrically operated actuators. Once the packs are sealed, the operator manually removes the product.

The seal temperature and pressure, and sealing time, can all be adjusted to suit the packaging type and digital controls ensure the machine produces consistent sealing results each time.

Examples of these machines include the HS34CF, HS35AC and HS36ACF. This type of sealer is preferred by mid-volume producers that want to scale up their production, as, in some cases, they can handle larger trays than hand sealers, as well as MAP packs and multi-pack sealing. This significantly increases speed and consistency of sealing, helping to improve efficiency. The automated sealing process also reduces human error to ensure a more uniform and consistent seal. For example, our customer Proper Tasty invested in our HS35AC machine, gaining a more consistent seal and doubling its product’s shelf life, whilst increasing throughput.

What is an automatic heat sealer?

Automatic sealers offer ultimate efficiency for businesses producing in high volumes. These machines automate the entire sealing process, from securing packs to applying a seal quickly and consistently. Unlike their hand or semi-automatic counterparts, they require minimal human intervention, which makes them ideal for large-scale operations such as central kitchens and ready-meal production lines.

The main benefits of using an automatic sealer are centred on efficiency and quality control. Machines such as our HS52C or HS60C can produce thousands of packs per hour, which substantially increases throughput. Because the sealing process is automated, it eliminates human error and ensures a uniform seal every time. This consistency extends product shelf life, reduces waste, and protects brand reputation.

Some models, like the HS55, are also designed with versatility and sustainability in mind and feature multiple material sealing as well as zero-film-waste systems, which further helps protect the bottom line.

Are you ready to boost your production line? Contact our team to learn more.

When you choose a heat sealer from Soken Engineering, you’re investing in equipment designed with a deep understanding of the engineering principles that underpin reliable sealing. Don’t just take our word for it, here’s what Sohel Patel, Managing Director at Halal Kitchen Ltd, has to say:

“Soken machines are built to last, we chose to go with them for their speed, reliability and performance of the machines in general. We purchased not 1 but 2, an HS52 & HS60 model. They are great robust machines that will do the job you want.”

Ready to explore how Soken Engineering’s heat sealing technology can help your business? Get in touch.