In today’s food-and-beverage manufacturing environment, pressure is growing from multiple directions: consumer demand for more sustainable packaging, regulatory regimes that increasingly penalise waste and non-recyclable material, and operational demands for high throughput and flexibility. Against this backdrop, manufacturers of ready meals, convenience foods, fresh fruit trays, and more need not only high-performance machinery, but they also need equipment that aligns with sustainability goals and regulatory compliance. That is where the HS55 from Soken Engineering Ltd comes into its own.

Designed as a high-volume automatic linear film and card sealer capable of up to 2,800 sealed packs per hour, the HS55 offers the speed, flexibility and reliability required by producers. Beyond speed, what really sets this machine apart is its zero-waste film feed and semi-profile cutting system. The machine is engineered so that during production there is zero excess film waste from the sealing process.

In practical terms this means no scrap film, no removal of excess film strips and no waste disposal. That zero-waste film feed system is not just a nice to have — in the context of growing regulatory and cost pressures around packaging waste, it becomes a strategic asset.

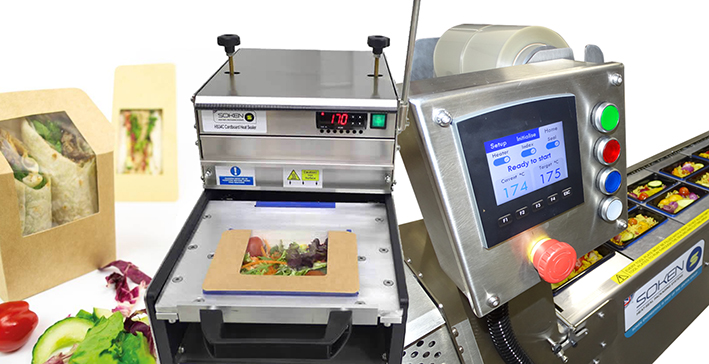

Soken Engineering HS55 series linear sealing machines

What “zero waste film system” means in practice

Let’s look a little closer at how the HS55 achieves this zero-waste performance, and what the benefit is on the factory floor:

- The machine employs an automatic film feed system combined with accurate semi-profile cutting, which ensures the film is aligned and trimmed precisely for each tray, rather than stamping the lidding film shape from a roll. Introducing the Soken HS55.

- A stepper-motor controlled indexing system means the film is always presented and positioned correctly, eliminating the risk of mis-aligned film that would otherwise mean wasteful trimming or rejected packs. Precise and waste free tray sealing with the HS55.

- Importantly, by eliminating the “tail” or “trim” film waste which is often inherent in traditional film feed systems (where residual lengths, overlaps, or margin losses add up) the HS55 eliminates film waste.

In practice that means a few key advantages: less film to purchase or stock, fewer rejects or wasted pack material, lower labour/time associated with film trimming or handling waste, and no film leftover that must be disposed or recycled. For a high-volume food packager, even small reductions in film waste translate into significant cost savings and operational improvements.

Linking zero film waste to regulatory and cost pressures: the EPR context

One of the biggest drivers pushing packaging operations to rethink film use and waste is regulatory change. In the UK (and increasingly across Europe) the rollout of the Extended Producer Responsibility for Packaging (EPR) regime is reshaping how manufacturers think about packaging materials, wastage, recycling and related costs. U.K. Government advice on extended producer recycling, (ERP), of packaging.

Under EPR for packaging, producers (or companies placing packaging into the market) above a certain volume are obliged to report how much packaging is used, what type, what material, and ultimately contribute financially to the cost of household packaging waste collection, sorting and recycling.

The base fees for 2025-2026 have been published: for example, plastic packaging is set at £423 per tonne for household waste disposal fees. That means that every tonne of plastic packaging you place on the market (which ends up as household waste) carries a significant cost. Extended Producer Responsibility for Packaging: 2025 base fees

What’s Next…

From 2026 onwards, the scheme will become more dynamic: in addition to tonnage, the recyclability of the packaging (via the RAM – Recyclability Assessment Methodology) will determine modulation of fees. Easier-to-recycle (green rated) packaging will attract lower fees; harder-to-recycle (red rated) packaging will incur higher costs.

In short: reducing your packaging tonnage, improving material recyclability and avoiding waste all help reduce financial exposure under EPR.

So how does the HS55’s zero film waste system help in this regulatory/cost environment?

- By reducing the amount of film used (and therefore the amount of film disposed of as waste) you reduce your tonnage of packaging input and waste – directly impacting your EPR payable obligation.

- By eliminating scrap/final‐trim waste you reduce indirect costs (waste handling, disposal, labour) which might not get flagged under EPR but still weigh on cost-of-packing.

- By enabling more efficient use of film, you improve material efficiency and demonstrate better sustainability credentials – which supports the “circular economy” narrative and may influence rating/modulation under future EPR regimes.

- In sectors where film waste is ignored or un-optimised, the hidden cost of wasted material plus EPR fee exposure is one of the biggest profit drains. The HS55 gives you a tool to control that cost.

In other words, investing in machinery which emphasises zero waste is no longer just beneficial from an operational viewpoint – it is a strategic move to mitigate regulatory and cost risk.

Beyond film waste: broader operational and sustainability benefits

While the zero waste film system is the headline feature in the context of waste and EPR, the HS55 offers other capabilities which enhance its value proposition:

- Flexibility: the machine supports both automatic index and manual index mode, allowing production flexibility depending on batch size or product variation.

- Tooling options: quick interchangeable tooling allows different tray shapes and sizes (card or film base) to be used on the same machine, so producers can diversify packaging types without buying separate machinery.

- Compatibility with eco-friendly trays and films: the HS55 is able to seal the latest eco-friendly trays and lidding materials, which aligns with transitions to recyclable or compostable packaging materials.

- High throughput: up to 2,800 sealed packs/hour (depending on tray size and film) means the machine is capable of serious production scale.

- Support and service: built by Soken in the UK, with spares held in stock and after-sales support. All of these contribute to reduced downtime, faster changeover, material flexibility and ultimately reduced risk of waste (material, time, labour) — again feeding into sustainability and regulatory readiness.

Why now is the time to act

For food producers and packagers, the intersection of sustainability pressure, regulatory change (EPR, recyclability criteria) and consumer expectations means that staying ahead of the curve is essential. Packaging waste tonnage, recyclability, and traceability are becoming non-negotiables.

The HS55 offers a timely solution for several reasons:

- Compliance readiness – With EPR charging based on packaging tonnage from 2025/26 onwards, and modulation based on recyclability from 2026, any reduction in film waste translates into lower liability and risk of higher fees.

- Material efficiency – Film is often one of the major variable costs in tray sealing; reducing waste directly impacts cost of goods sold and helps protect margin.

- Sustainability credentials – Being able to claim “zero film waste from the sealing feed system” is a strong statement for internal (CSR) and external (customer/retailer) sustainability reporting.

- Future-proofing – As packaging materials evolve (e.g., move to mono-films, recyclable seal films, hybrid trays), having a machine capable of handling eco-friendly films and reducing waste gives you agility.

- Operational gain – Zero scrap film means less downtime, fewer rejects, less waste disposal handling. It also frees up operational time to focus on production rather than waste mitigation.

In effect, manufacturers who ignore film waste optimisation may find themselves not only paying more in raw material and waste disposal, but also facing higher EPR packaging charges and reputational risk. The HS55 gives you a tangible route to mitigate that.

Conclusion

In summary, the Soken HS55 provides an optimal combination of production efficiency and sustainability compliance. Its zero-waste film feed and semi-profile cutting system is more than a manufacturing nicety — it directly addresses several critical pressures facing manufacturers today: material cost, waste handling, regulatory compliance (especially under EPR), and sustainability reporting.

In a market where packaging waste tonnage and recyclability now carry real financial implications, investing in machinery which actively reduces waste helps you stay ahead, protect margin and demonstrate responsible operations. If you are a ready meal, fresh tray, convenience pack or sandwich manufacturer looking for a sealing machine that combines high throughput, flexibility and waste-minimised performance, the HS55 deserves serious consideration.